Sunday, December 7, 2014

Humidor Project

Big post coming soon. I've been working with the Honeywell HIH6130 humidity sensor. I enjoy the occasional cigar but I'm terrible at keeping it humid. I'm going to use the sensor to display a LED when the humidity drops lower than the preferred range. It will cover some bit twiddling and I2C communication. This was a great project to get me more comfortable with both topics.

Sunday, November 9, 2014

Burrrrr.....It's not that cold

Went ahead and tried a little experiment this weekend with putting my peltier chiller to a test. I took a medium sized foam cooler, modified the top of the cooler and hot glued the fan and cut some intakes out. The fan pushes cool air away from the cooling surface of the peltier.

I haven't bought the materials to make to create the larger chamber to fit my 3 gallon fermentor because I want to get an idea on how one peltier device will perform. I placed the sensor in the box and cut a small hole for the cables to run through. I didn't add any other insulation nor did I seal the holes I made for wiring so it wasn't air tight. Rather than controlling the temperature in this case, I simply let the cooler run to see how cool it got. After about an hour, I didn't see anymore reduction in chamber temperature. Room temp when I started was about 75 F. After about an hour, it stayed pretty steady between 62-64 F which is over 10 F cooler than ambient. If I had a larger chamber, I'd have some more losses and it would take longer to even get near this chamber. I may try plugging up a few of the cracks and seal the lid to see how much impact that makes. This was a quick crude test. My plan was to use thick 2" thick insulation surrounded by a wood frame which will have better insulating properties than my cheap cooler. Made a graph of the temperature versus time.

I didn't loose hope but I think its important to do small scale tests to ensure your making progress. I still learned quite a bit from doing this project even up to this point so I'll try a few more things with my setup.

- Insulate/seal the chamber better

- Let it run longer

Thursday, October 9, 2014

Chiller Control Board Up and Running

I went ahead and double checked all my connections for my hand wiring on the underside of the board with my multimeter. I got a bunch of beeps which is good news. I went ahead and used jumpers to connect to the 4 pins I'm using on the Raspberry Pi at this time. There may be more parameters I end up measuring later. The temperature sensor hooked up to the three pin terminal. All the "high power" electronics including the fans and Peltier are wired into one terminal since they are all the same operating voltage and it just draws more current. They are hooked in parallel to be precise. I did use larger wire when wiring these lines because there was going to be more than 5A running through these. After I wired everything it up, I powered it through another screw terminal and the board, sensors and fan all functioned properly. The RasPi didn't do anything odd because I powered through a convertor and had no issues controlling the MOSFET. I tried to power it simply from a 12V to 5V convertor only with some capacitors wired in but the Pi didn't function properly.

In the program, a temperature range is set where you'd like to ferment. The Peltier turns off and on based on that temperature reading. I want to make it a little more intelligent when it comes turning off and on. I don't want it to run continually simply because it doesn't have to.

|

| Peltier Wired Up |

|

| Wired Setup |

I am pretty pleased with how it is coming together. Before I go ahead and build the chamber, I think i may do a test just in a cardboard box to see how cool it gets with one device. I'd figure out the losses and predict the temperature but I do that in my day job so I'll wing this one.

Saturday, October 4, 2014

Fermentation Control Board

I wired all the components from a schematic I made. Took a few steps to get to the finished product. Below is a circuit demonstrating the concept and it incorporates a few things.

The Raspberry Pi reads the temperature and switches the MOSFET from another GPIO pin. The x2 fans and Peltier device are all on the same MOSFET since they need to turn on at the same time.

After I confirm all connections, I'll go ahead and test it out!

- A power jack

- NPN Transistor

- Peltier Device

- Digital temperature sensor

- x2 Fans

- One to cool the heat sink

- One to circulate the chamber

The Raspberry Pi reads the temperature and switches the MOSFET from another GPIO pin. The x2 fans and Peltier device are all on the same MOSFET since they need to turn on at the same time.

|

| Schematic of Diagram |

I ended up with a large power block that operates at 12 V and is capable up to 10 Amps. The Peltier can pull up to 5 A and the fans about 1 A and the Raspberry Pi another amp probably. My goal was to power everything from one source so I didn't have all these power cords and I could easily mount it to the top of the cooler. Due to the large current draw on some components, I didn't design a PCB board for this. Instead I went with a perfboard. All the components are 12 V except for the Raspberry pi so to power that, I purchased a small buck power converter for a few bucks on Amazon. It works very well and steps down the 12V to 5V and the raspberry pi can be powered via USB then. I mounted this directly to the board itself.

I laid it out on a piece of "perfboard paper" which makes it very easy to plan how to mount the components. If you Google for it you can find it easily online. I drew the layout some-what to scale on the size board I was using and labeled everything.

|

| Perfboard Layout on Piece of Paper |

After I laid everything out on the board, I went ahead and wired the components with wires on the bottom. I used lower gauge wire for higher amp lines and just used some 22 gauge for the smaller stuff. Pins on the left hook to Raspberry Pi and I have 3 terminals.

- Temp Sensor Terminal

- Fan and Peltier Terminal

- Power Terminal

|

| Wired Perf Contorl Board |

Friday, October 3, 2014

Still Here...

It has been awhile but I've been pretty busy. I got some work to post on the fermentation controls fo sho.

Saturday, August 16, 2014

DS18B20 Digital Temperature Sensor to the Pi

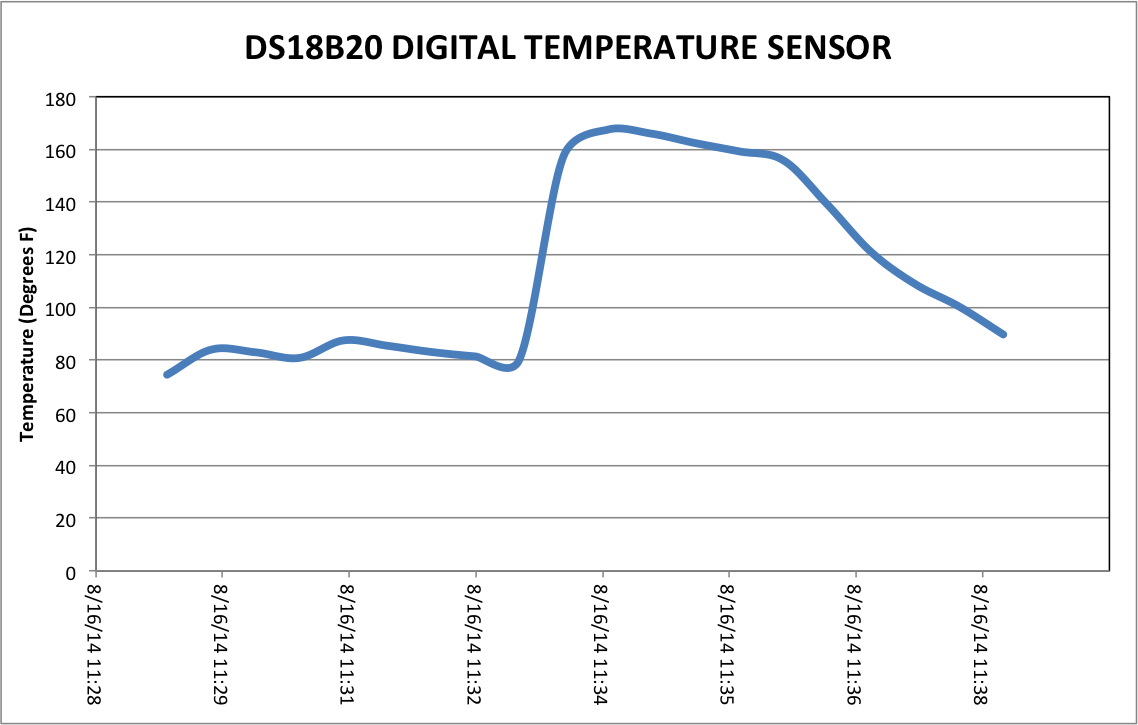

Was able to download and configure this temperature sensor on the raspberry pi. I incorporated it into my current data logging program to write the value to the file and I also exported it into excel. It was really easy to hookup and had accurate readings. I got it from Adafruit and it has a good walkthrough on it. Now that I have the temperature sensor setup. I am going to use that to control a small fan and Peltier device in a fermentation chamber I am going to build. I started to design it but have to figure out some more stuff. Below is the sensor hooked up and a graph of the data. I stuck it in some hot water to get some dramatic data....wooooooo. I've posted the data logging file here on on Github. I'll have a full page on my site in regards to the project when it is done.

Thursday, August 14, 2014

Beer Data Logger Progress

Booted up the raspberry pi again and had plenty of updates. I started the python script to log the data on a time interval. Fermenting usually takes 2-4 weeks so it will be logging for a relatively long time. I just started by having it record numbers since I didn't have sensors hooked up but I download a program called 'Screens'. There is a nice tutorial/overview in this link. With this I can have the program run in the background after I disconnect via SSH and I can reconnect later to download the data file or reattach to the 'screen' that is running the program to view the current temperatures. I'm working on incorporating it into a controlled fermentor that logs and maintains a set temperature. More to come...

Here you can see the data file recording with time stamps, temperature and lux (numbers made up). It also displays it in the terminal as it records.

|

| Screen Shot of Data File and Display |

Sunday, August 10, 2014

Racked the Double IPA to Secondary

So far so good, just racked it to the secondary and added first addition of dry hops. Smell and color are both really good.

Sunday, August 3, 2014

Changes to blog/site

You may see some links pop up on my blog post. Those will direct you to a site that will have 'Project Pages' categorized. I could add a bunch of pages to the blog site although it wouldn't be very well organized. So those links will direct you to the other site that will have dedicated pages to certain projects I am working on. General tinkering will still take place here!

ATTiny 85 Blink

I just remembered today that I had another Atmel chip that I had sitting around. I originally purchased it to program with the Arduino, which failed. I've been working through the AVR book some more. Recently did some analog stuff however I have a lot of time in between working on it so I forget a lot of what I had previously done. Takes a lot more time to work through things but it is starting to get engrained. The ATTiny85 gets programmed using the same hardware/processes, only has less memory and fewer pins. I programmed it to do a simple blink program just to see if I was successful.

Turned out I was, I'm starting to think how I could incorporate this into a project eventually.

|

Starting with AVR Programming and ATMega Chips

I really enjoy microcontrollers but wanted to understand them in more detail. I saw on O'Reilly media they were having a book sale and noticed one specific to AVR programming. It essentially is a book of programming the chip series that is used on the Arduino and many more. The book is called Make: AVR Programming and I happened to get it 50% off. It takes you through three levels including beginner, intermediate and expert. It doesn't take much to get started. I purchased a few components I did not have on hand and the biggest purchase is an AVR programmer. I bought the AVRISP mkII from Digikey (I think it is now discontinued?). There are others that will work as well. I've started to walk through the book and worked on some basics. Everything is coded in C and the book walks you through on installing all the necessary programs as well. The image to the left is just an example of controlling multiple LED's. I altered the code several times and created several different patterns. Most recently I had the chip hooked up to the computer using Serial-USB communication. Everything I've done thus far has been outputs. The next chapter is inputs so the famous push button example will be up next. Here is a video of one of the patterns I created.

AVR LED PATTERN

Saturday, March 1, 2014

Bluetooth Speakers are Complete

I finished my bluetooth speakers that hook up to some old computer speakers. Streaming music from my phone or computer from anywhere in my home. It is not as loud but I could always incorporate an additional amplifier into the circuit. Before I packaged it up, I had everything completed on a perfboard and ensured everything was working. It was not powering at first but it was because I forgot to Ground the board :-/...after that everything worked great.

I packaged it up in a small project box with a 3.5 mm audio jack and it is powered from a 3.3V wall adapter which supplies plenty of current for this project. The two LED's are status LED's to see when someone is connected. Fun and pretty simple project putting some old speakers to use.

I packaged it up in a small project box with a 3.5 mm audio jack and it is powered from a 3.3V wall adapter which supplies plenty of current for this project. The two LED's are status LED's to see when someone is connected. Fun and pretty simple project putting some old speakers to use.

Monday, February 10, 2014

Bluetooth Speaker System

We had some old computer speakers sitting around that we utilize in the living room for our ipod or computer. Since I'm a lazy bum I got sick of standing up and "thumbs downing" songs on Pandora or changing songs when we are at the table or entertaining so I went the route of making those suckers bluetooth where we can stream through our phone or computers from anywhere in out place.

I got the bluetooth module from Sparkfun and it has a lot of great documentation on it in regards to getting started. I bought the RN-52 breakout board for convenience but you could go cheaper just buying the module. The speakers I have are 2 speakers and a subwoofer so I cut the audio jack off to see what wires I had. Turnout I had the left speaker, right speaker and a common ground among them. These speakers are externally powered so the signal is already amplified. In the case you would be using headphones or low powered speakers there would be no need to amplify the signal.

I intend on packaging everything on a protoboard and in a project box. I'm going to power it from a 3.3v wall adapter and add an audio jack if I ever change speakers in the future I won't have to hardwire anything. Functionality wise it works great!

I got the bluetooth module from Sparkfun and it has a lot of great documentation on it in regards to getting started. I bought the RN-52 breakout board for convenience but you could go cheaper just buying the module. The speakers I have are 2 speakers and a subwoofer so I cut the audio jack off to see what wires I had. Turnout I had the left speaker, right speaker and a common ground among them. These speakers are externally powered so the signal is already amplified. In the case you would be using headphones or low powered speakers there would be no need to amplify the signal.

|

| Prototype of Bluetooth Speakers |

Wheatstone Bridge Hydrometer

So I was not making the wheatstone bridge for my health. My intent was to build a hydrometer for home brewing. There are multiple ways of doing this but I wanted to play around with the strain gages. The principle being the buoyancy of a ping pong ball bolted at the end of a beam would vary as a function of a fluids density or Specific Gravity which is the typical measurement when home brewing.

This was my crude build and attempt at utilizing it as such but was not overall pleased with the results, fun idea. I had a few other ideas for making a hydrometer but ditched them because of cost and complexity to replace a simple glass tube.

Saturday, January 25, 2014

Wheatstone Bridge with the Arduino

Well...I gave strain gages a shot with the arduino and the INA125 amplifier. When I was designing my circuit I referenced a few other people who tried to apply a wheatstone bridge with an arduino. They were utilizing it as a beam in bending to measure mass ranging from 0 - 500 g. I was trying to apply it in much more sensitive application picking up a force on the beam that was 0 - <1 lb. Most people had difficulty in amplifying the signal because they could not balance the bridge or utilized a quarter or half bridge. I opted to use a full wheatstone bridge but it was difficult to get the resolution I needed for a few reasons. They had some reasonable results with the amount of force they were trying to measure.

- The arduino can only handle a 5V signal. I was forced to use a 5 v source for my bridge which does not leave a large range of output signal for the forces I am reading.

- After mounting all the strain gages and wiring, there is some slight variation in the resistances of the bridge which shows up as an amplified signal. I was already forced to limit my output range to a few volts.

- The resistance I had set for amplification was very touchy. I had to amplify the signal significantly because I was trying to read very small changes in force. A change of a few ohms on the resistance changed the amplification significantly and the amplifier would become saturated reading the maximum voltage.

- Wiring of the strain gage makes a BIG difference. I would jiggle and bend my wires and peg the output voltage. I probably could have done better with this but didn't want to invest anymore money.

|

| Full Wheatstone Bridge with the Arduino |

I was able to notice some change but it was not consistent and responsive. It was a fun try but don't think I will invest much more time or money into the project. I might start looking for alternative methods of measuring very small changes in force with a common micro-controller. It was interesting working with the Wheatstone bridge and it was the first time I had used the INA125.

|

| INA125 wired to bridge and Arduino |

I have some ideas so stay tuned for what I come up with next. If anyone has suggestions or experience using the INA125 or wheatstone bridges let me know and I'll give it a shot.

Tuesday, January 7, 2014

123D Circuits

Just saw this from Autodesk. I think its pretty great idea and seems pretty functional from the little I have tried. Anyone else give this a try yet?

Subscribe to:

Posts (Atom)